Execution Tank Gauging System

Execution Of Tank Gauging System + IRAN

Tank gauging means liquid measurement in large storage tanks to determine product volume. You need to keep track of how much raw material you have on site and how much storage space you have available Tank Gauging System ensures accurate level, temperature, and pressure measurements for inventory control, oil movement and overfill prevention, securing efficient operations.

Monitoring and control of bulk liquids during processing, transportation and storage is challenging.

For all of these challenges, ISTA KHERAD PARSEH (IKP CO) is your partner to support you to overcome these challenges.

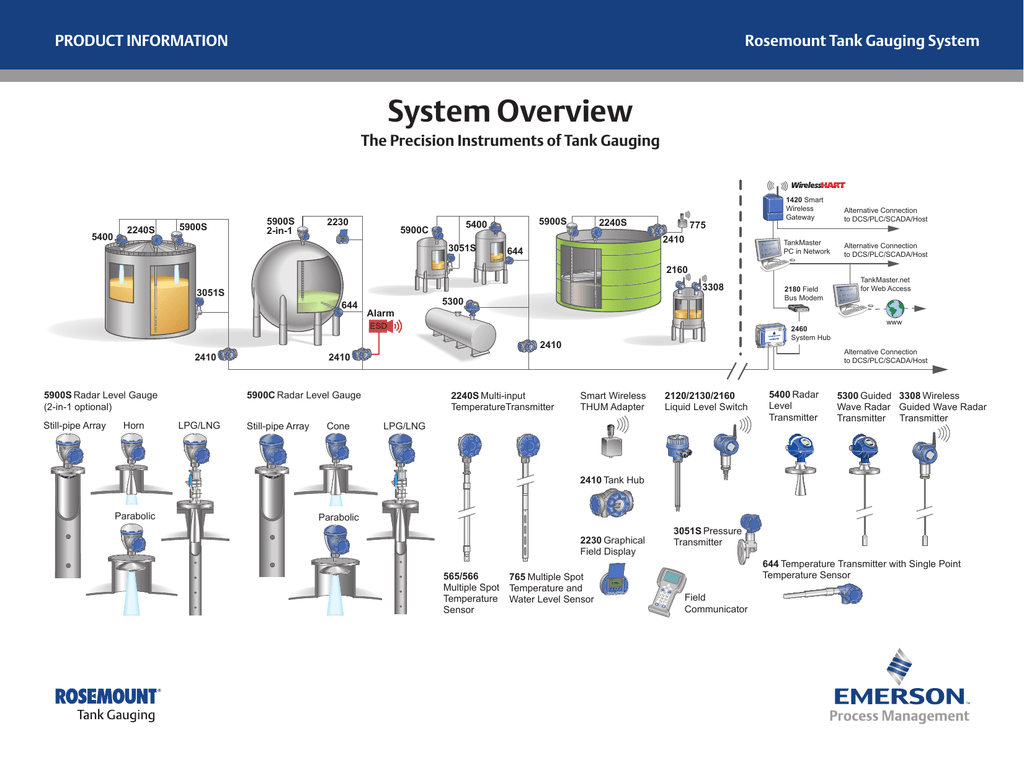

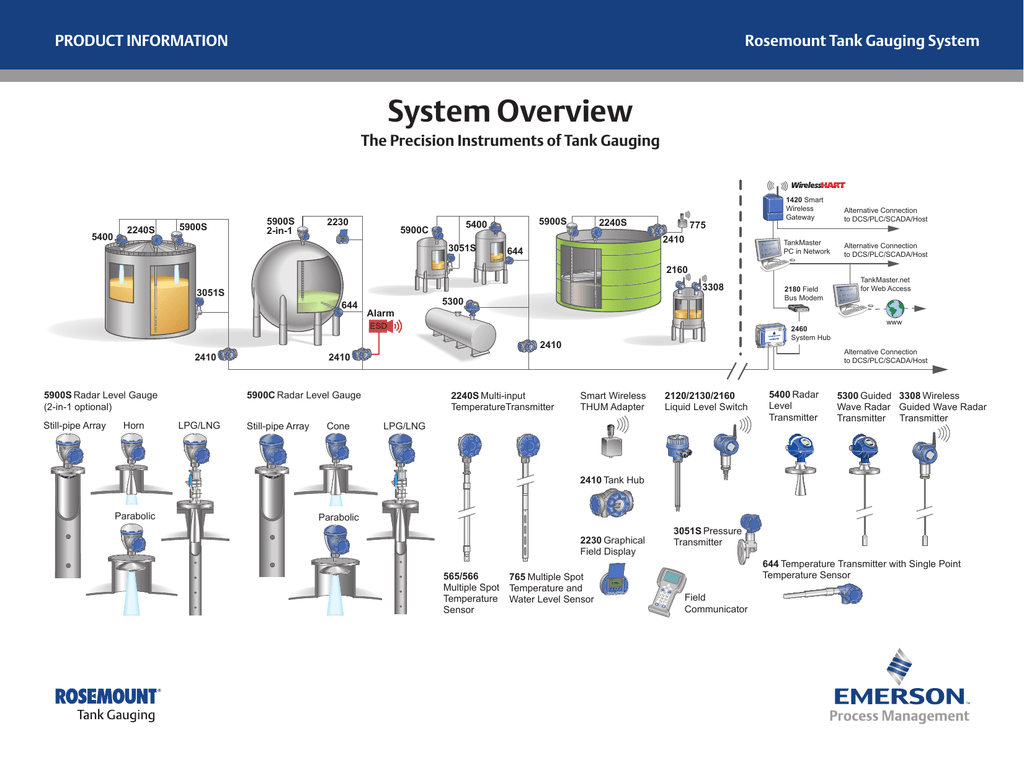

SYSTEM COMPONENTS

TGS (stands for Tank Gauging System) is package consist of several parts as follows:

1- Radar or Servo level transmitter measures main liquid level and volume.( meet the NMi and PTB requirements)

2- Multipoint average temperature transmitter measures average temperature of liquid and liquid in bottom of tank.

3- Local indicator shows measured or compensated values and installed in bottom of tank to help operator see tank status easily.

4- Pressure transmitter was used for density measurement.

5- Compensator collects all devices data and calculated mass or compensated volume depends on fluid and ambient temperature or other process conditions. This task will be done by master device provides output in different digital field bus formats. Local indicator or servo level transmitter can play as master device on a tank.

6- Data concentrator receives digital buses from field and transmits to control or monitoring system. This part is able to log all received data too.

MEASURED & CALCULATED PARAMETERS

Tank Gauging System can provide measured and calculated parameters as follows:

Main liquid level Correction Level

Average Temperature Temperature of each point

Fluid density

Water (liquid) bottom Level

Bottom Pressure ,Middle Pressure, Top Pressure

Gross Obsereved Volume (GOV)

Net Standrd Volume (NSV)

Mass

Low and Low-Low alarms ,High and High-High alarms

Tank filled Percentage

Liquid & Gas phase Temperature

Flow Rate (Rate of change of level)

Volumetric Flow Rate

Our TGS Project Team is Trained and certified by the well-known TGS manufacturers like EMERSON and Enderss+ Hauser.

Our experience in various important projects that in some cases was integration of old TGS systems to new ones and our good relationship with manufacturers to become update about new changes and technologies are the key of our success on TGS projects with EMERSON and Endress+ Hauser systems.

We serve engineering, procurement, Pre commissioning, commissioning, Training and maintenance services on TGS projects in both internal and external projects.

Our taken AC (Acceptance Certificates) from Customers is our Capital and pride to become your partner on TGS projects.

EMERSON / TGS Products

Rosemount™ TankMaster™ Inventory Management Software

Rosemount™ 5900S Radar Level Gauge

Rosemount™ 2240S Multi-input Temperature Transmitter

Rosemount™ 765 Multiple Spot Temperature and Water Level Sensor

Rosemount™ 3051S Coplanar™ Pressure Transmitter

Rosemount™ 2230 Graphical Field Display

Rosemount™ 2410 Tank Hub

Rosemount™ 2460 System Hub

ENDRESS + HAUSER / TGS PROUCTS

NMR84 Level Radar Transmitter

Endress+ Hauser NMS80 Servo Level Transmitter

Endress+ Hauser NMT539 Multi Average Temperature Transmitter

Endress+ Hauser NRF80 Tank Side Monitor

Endress+ Hauser PMP71 Pressure Transmitter

Endress+ Hauser NXA820 Tank Scanner

Endress+ Hauser NXA821 Data Concentrator

Endress+ Hauser NXA822 Host Link